Experience Our Quality Infrastructure

-

Hydraulic Machine 800 - 1 PCs

According to the industrial requirements, a large variety of hydraulic presses are available. Arbor presses(for piercing holes into metals, stamping, marking inscriptions, etc..), laminating presses(for laminating the identity cards, certificates, and even book covers), C-frame presses(for straightening, drawing, and assembling work), pneumatic presses(for assembling, drawing, punching, and vehicles braking system), and H-frame presses(can perform more than one press operation) are some types of hydraulic presses. A hydraulic press will provide smooth pressing and even pressure on the entire ram. The pressure relief valves embedded in most of the hydraulic presses will control the pressure of the system. A double acting cylinder used in many hydraulic presses can lift a tooling attached ram. A person can easily choose a hydraulic press by considering the size, pressure, and speed.

-

Hydraulic Machine 300 - 1 PCs

According to the industrial requirements, a large variety of hydraulic presses are available. Arbor presses(for piercing holes into metals, stamping, marking inscriptions, etc..), laminating presses(for laminating the identity cards, certificates, and even book covers), C-frame presses(for straightening, drawing, and assembling work), pneumatic presses(for assembling, drawing, punching, and vehicles braking system), and H-frame presses(can perform more than one press operation) are some types of hydraulic presses. A hydraulic press will provide smooth pressing and even pressure on the entire ram. The pressure relief valves embedded in most of the hydraulic presses will control the pressure of the system. A double acting cylinder used in many hydraulic presses can lift a tooling attached ram. A person can easily choose a hydraulic press by considering the size, pressure, and speed.

-

Hydraulic Machine 100/150 - 1 PCs

According to the industrial requirements, a large variety of hydraulic presses are available. Arbor presses(for piercing holes into metals, stamping, marking inscriptions, etc..), laminating presses(for laminating the identity cards, certificates, and even book covers), C-frame presses(for straightening, drawing, and assembling work), pneumatic presses(for assembling, drawing, punching, and vehicles braking system), and H-frame presses(can perform more than one press operation) are some types of hydraulic presses. A hydraulic press will provide smooth pressing and even pressure on the entire ram. The pressure relief valves embedded in most of the hydraulic presses will control the pressure of the system. A double acting cylinder used in many hydraulic presses can lift a tooling attached ram. A person can easily choose a hydraulic press by considering the size, pressure, and speed.

-

Magnetic Drill Machine - 1 PCs

A magnetic drill press is a portable drilling machine equipped with an electro magnet or permanent magnet base and is used for making holes in metal. A Magnetic drill press is a machine tool fitted with a cutting tool attachment and an electromagnet, is used for drilling holes in metals. A magnetic drill press is attached with cutting tools called as a core drill, this core drill is hollow from inside but has cutting edges on the surface and on teeth. A magnetic drill press is also called a magnetic core drilling machine, magnetic drilling machine, mag base drill, magnetic drill machine, mag base drill or mag drill.

-

Digital Thickness Meter - 1 PCs

A thickness gauge is a device used to quickly and easily measure the thickness of a material. A thickness gauge is useful for many industries but is most commonly used in engineering and manufacturing to help ensure material thickness complies with industrial standards and regulations. As well as measuring the thickness and density of a material, a thickness gauge can be used as an additional quality assurance tool in industries such as automotive, to measure the uniformity of material and help identify hidden damages or imperfections.

-

Dial Gauge - 1 PCs

Dial gauges are used for checking flatness of surfaces; parallelism of bar and rods; and detecting small differences if any in linear measurement of identical objects. A dial gauge is also used for measuring concentricity of round objects. These are available in inches as well as in millimetre. Inch dial gauges of 0.001 “measuring accuracy is in general use, but gauges are available up to the accuracy of 0.0001”. The commonly used metric dial gauge has an accuracy of 0.01 mm.

-

Electric Crane & Hoist ( Capacity - 5 Tones )

An electric crane and hoist with a capacity of 5 tonnes is a heavy-duty industrial machine used for lifting and moving heavy objects or materials. It consists of several components, including the crane structure, electric motor, gearbox, hoist drum, wire rope, and control system. The crane structure is designed to support and move the hoist and its load. It usually consists of a horizontal beam (bridge), supported by two vertical beams (legs) that are fixed to the ground. The bridge can move back and forth along a runway, which is mounted on top of the vertical beams.

-

Welding Rectifier 400 - 1 PCs

Welding rectifiers are essentially transformers with an electrical device as a rectifier which changes AC to DC. Rectifier basically consists of Silicon diodes, which ensure the flow of current in one direction giving DC output. This is most commonly used with Arc welding equipment. A rectifier can be used to change the current from AC to DC by using a process called full-wave rectification. This is done by using diodes that allow current to flow in only one direction. The diodes are connected to the AC power source and to the welding machine.

-

Welding Transformer - 1 PCs

The transformer, housed in a welding machine, is used to convert the high-voltage input or, primary power, from the wall plug and this is usually from 208 to 600 volts, with a low alternating current (AC) from 15 to 55 amps. This is transformed in the secondary power side to a lower voltage of up to 80 volts and a range of welding currents up to 1000 amps AC or more, depending on the process and equipment. Welding Transformers are used in AC machines to change alternating current from the power line into a low-voltage, high amperage current in the secondary winding. A combination of primary and/or secondary taps on the welding transformer are commonly used to provide a macro adjustment of the welding current, as well as adjustment of secondary voltage. Transformer ratings for AC machines are expressed in KVA (kilovolt-amperes) for a specified duty cycle.

-

Pug Cutting Machine - 1 PCs

The CPG-NM PUG cutter is a semi-automatic, portable gas cutting machine ideal for straight, circular, and bevel cuts. Affordable price, ease of use, and portability make this flame-cutting machine popular all over the world. Thanks to the “NozzleMix” technology, there is no risk of backfiring when cutting. A die-cast aluminum body with ventilation holes prevents overheating of the motor and electrical components.

-

Hand Cutting Machine - 1 PCs

“Hand cutter means the cutting tools that are used to remove some material from the workpiece.” Hand cutters mostly used for household working and construction sites. There are multiple kinds of cutter tools available in the market and all cut different materials.

-

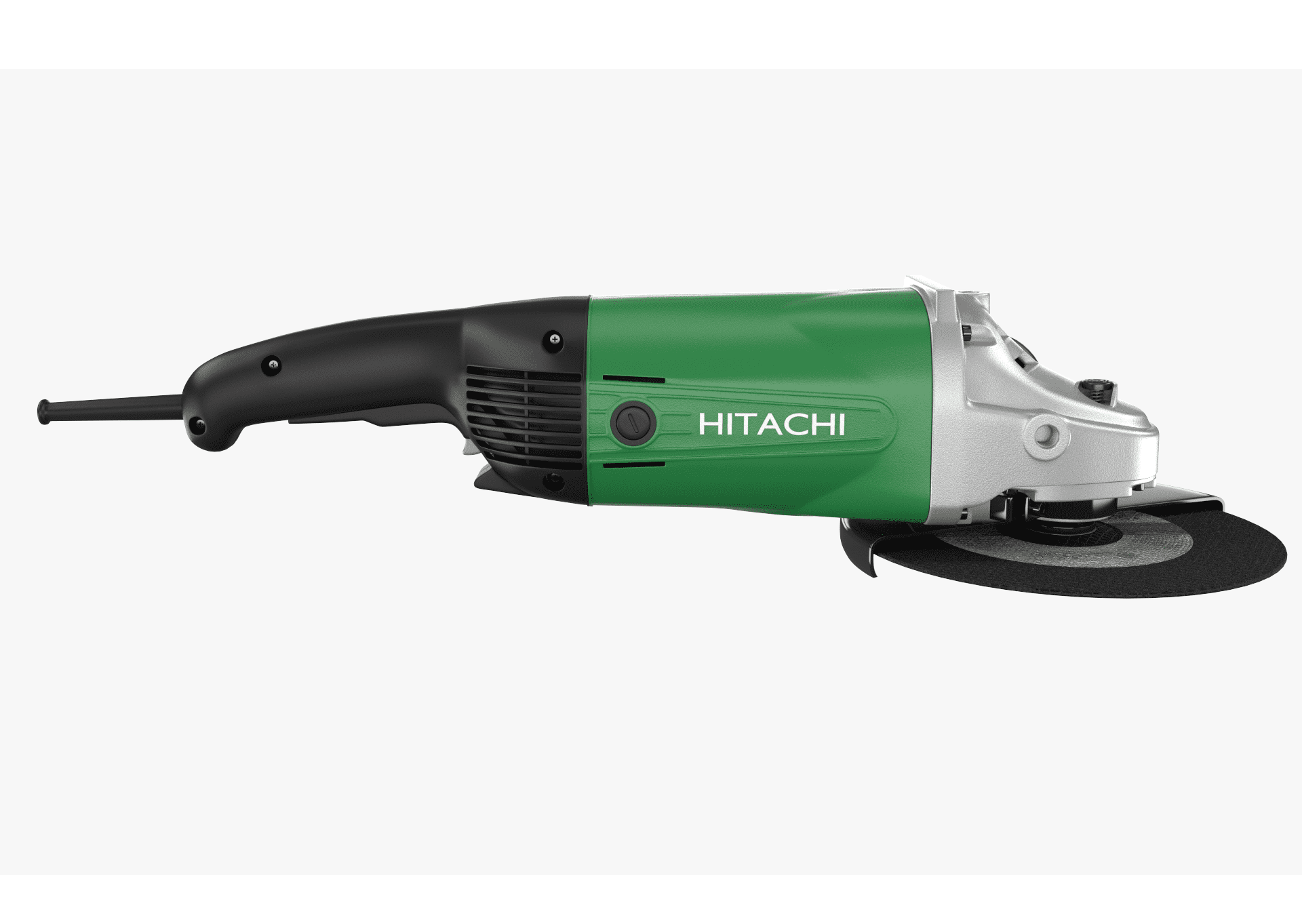

Hitachi Grinder - 3 PCs

An angle grinder is a handheld power tool that can be used for a variety of metal fabrication jobs that include cutting, grinding, deburring, finishing and polishing. The most common types of angle grinder tools are powered by electricity; either corded or battery powered. It's the most versatile tool in the box and should be a staple of any shed or workshop but we aren't just saying that because they work perfectly with many of our abrasives! An angle grinder tool with the right disc can replace numerous tools and make the most tedious, labour intensive jobs quicker and easier.

-

CO2 Welding Machine - 1 PCs

A CO2 welding machine is a relatively new kind of welding machine that is gas-powered. This means that there is no need for a flame, and you do not need any oxygen to weld. The CO2 can come from a variety of different sources including natural gases, oxygen, and other liquids such as methanol or diesel. The CO2 can be supplied at very high pressure, and usually, a mixture of both compressed air and gas is used. This gives it a lot of energy that is very powerful, and able to meet the needs of the user very efficiently.